Thermal cameras operate based on the principles of thermography, which involves the detection and measurement of infrared radiation emitted by objects. These cameras utilize specialized sensors, known as microbolometers, to detect the heat signatures of different objects and convert them into visible images. Thermal cameras have become essential tools across various industries, from construction to healthcare, due to their ability to visualize heat patterns. This expansion will dive deeper into the workings of thermal cameras, their applications, and practical advice for maximizing their effectiveness. When an object emits infrared radiation, it interacts with the sensor in the thermal camera, causing changes in the resistance of the microbolometer. This change in resistance is then converted into an electrical signal, which is processed and translated into a thermal image by the camera’s software.

The Role of Infrared Radiation

Infrared radiation is a type of electromagnetic radiation with wavelengths longer than visible light. All objects with a temperature above absolute zero emit infrared radiation. The intensity of this radiation increases with temperature, making it possible for thermal cameras to detect variations in heat.

Thermal imaging offers a unique perspective by capturing the invisible heat emitted from objects. This aspect makes it invaluable for applications where traditional cameras fall short, such as seeing through smoke or detecting heat leaks in buildings.

Understanding Infrared Spectrum

The infrared spectrum is divided into three categories: near-infrared, mid-infrared, and far-infrared. Thermal cameras typically operate in the long-wave infrared (LWIR) range, which is most effective for thermal imaging. This range allows for the detection of emitted heat without interference from visible light.

From Microbolometer to Image

The microbolometer sensor, typically made of materials like vanadium oxide or amorphous silicon, is crucial in detecting this radiation. It doesn’t require cooling, making it more versatile and less expensive than other types of sensors. The microbolometer absorbs infrared radiation and its temperature changes, altering its electrical resistance. This change is converted into a voltage signal, which is then processed by the camera into a digital image that represents temperature variations across the observed scene.

Advancements in Microbolometer Technology

Recent advancements have improved the sensitivity and resolution of microbolometers, expanding the potential applications of thermal cameras. For example, newer models can detect temperature differences as small as 0.05 degrees Celsius, providing more detailed images.

Types of Thermal Cameras

There are two main types of thermal cameras: uncooled and cooled. Each has its own set of advantages and applications.

Uncooled Thermal Cameras

Uncooled cameras are more common and use microbolometers that do not require cooling systems. Their simplicity and cost-effectiveness make them ideal for a wide range of applications, from building inspections to wildlife monitoring.

Case Study: Building Inspections

In building inspections, uncooled thermal cameras are frequently used to identify insulation gaps, moisture intrusion, and electrical faults. For instance, a property manager might use these cameras to pinpoint areas where heat is escaping during winter, allowing for targeted insulation improvements.

Cooled Thermal Cameras

Cooled cameras, on the other hand, use cooled detectors to achieve higher sensitivity and image quality. These cameras contain cryogenic cooling systems that maintain the detector at a very low temperature, minimizing thermal noise. This makes them suitable for high-precision applications, such as military targeting systems and scientific research where detecting minute temperature differences is critical.

Precision in Scientific Research

In scientific research, the precision of cooled cameras allows for detailed studies of thermal phenomena. Researchers might use these cameras to study volcanic activity, analyzing temperature fluctuations to predict eruptions.

Applications of Thermal Cameras

Thermal cameras have a wide range of applications across various industries. Their ability to detect heat signatures where visible light fails makes them indispensable in many fields.

Surveillance and Security

In surveillance, thermal cameras are invaluable for monitoring and security purposes. They can detect intruders in total darkness, through fog, and even in challenging weather conditions. For instance, they are often used at borders to detect unauthorized crossings.

Enhancing Border Security

Border patrols use thermal cameras to monitor vast areas without the need for extensive lighting, reducing operational costs and minimizing detection by smugglers. The ability to detect heat signatures from a distance provides a significant advantage in maintaining security.

Firefighting

In firefighting, thermal cameras are crucial for identifying hotspots and individuals in smoke-filled environments. Firefighters can see through smoke, locate people in need of rescue, and determine the hottest parts of a fire to strategize firefighting efforts.

Saving Lives in Emergencies

Thermal cameras have been pivotal in saving lives during house fires by enabling firefighters to quickly locate trapped individuals. They also assist in assessing structural stability by identifying areas weakened by heat.

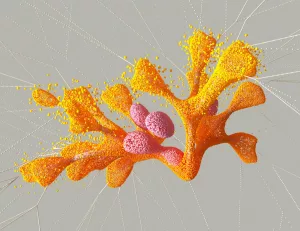

Medical Imaging

In the medical field, thermal cameras are employed for imaging applications, such as detecting heat patterns in the human body. They can be used to spot inflammation or poor circulation, providing non-invasive diagnostic options.

Non-Invasive Diagnostics

Doctors use thermal imaging to monitor inflammation in joints, providing a visual representation of areas affected by conditions like arthritis. This non-invasive method gives patients a comfortable diagnostic alternative.

Industrial Inspections

In industrial settings, these cameras are utilized for inspections to identify potential issues, such as overheating machinery or faulty electrical connections. For example, in an electrical substation, thermal cameras can detect hot spots that indicate potential failures, allowing for preventive maintenance.

Preventive Maintenance in Industry

Industries employ thermal cameras to monitor equipment health, preventing costly breakdowns. For instance, a manufacturing plant might use thermal imaging to ensure that conveyor belt motors are operating within safe temperature ranges, preventing unexpected downtime.

Wildlife and Environmental Studies

Thermal cameras are also used in wildlife and environmental studies to monitor animal populations without disturbing them. For instance, researchers can observe the nocturnal habits of animals or track elusive species in dense foliage.

Tracking Endangered Species

Conservationists use thermal imaging to track endangered species like tigers in dense forests. This non-intrusive method helps gather data on population health and movement patterns, assisting in conservation efforts.

Accuracy and Limitations

While thermal cameras are highly effective in detecting heat signatures, they do have certain limitations. Understanding these is crucial for accurate analysis and decision-making.

Factors Affecting Accuracy

- Distance: The farther the object, the less accurate the temperature reading. Thermal cameras have specific ranges within which they are most effective.

- Emissivity: This is the efficiency with which an object emits infrared radiation. Materials with low emissivity, like shiny metals, can reflect infrared radiation, leading to inaccurate readings.

- Environmental Conditions: Weather conditions, such as rain or fog, can affect thermal imaging. High humidity can also absorb infrared radiation, impacting the clarity of the thermal image.

Overcoming Limitations

To mitigate these limitations, users can calibrate their cameras regularly and adjust settings based on environmental conditions. For higher accuracy, using a combination of thermal and visual images can provide more context and improve decision-making.

Practical Tips for Using Thermal Cameras

Here are some practical tips to maximize the effectiveness of thermal cameras:

- Calibration: Regularly calibrate the camera to ensure accurate readings, especially in environments with fluctuating temperatures.

- Training: Ensure operators are well-trained in interpreting thermal images. Misinterpretation can lead to incorrect conclusions and decisions.

- Use in Combination: Complement thermal imaging with other diagnostic tools for comprehensive analysis, particularly in complex scenarios like building inspections.

- Emissivity Adjustments: Adjust the camera settings based on the emissivity of the materials being observed to enhance accuracy.

Detailed Example: Electrical Inspections

During electrical inspections, adjusting for emissivity is crucial. For instance, electrical panels often have components made of different materials. Adjusting settings to account for these differences ensures that hot spots are accurately identified and addressed.

Real-World Examples

Consider a case where a manufacturing facility used thermal cameras to detect overheating in machinery. By identifying hot spots early, they were able to prevent costly downtime and repairs. In another instance, a wildlife conservation group utilized thermal imaging to track endangered species at night, gathering crucial data without disturbing the animals.

Case Study: Urban Infrastructure

In urban areas, thermal cameras are used to monitor infrastructure like bridges and tunnels. By identifying temperature anomalies, maintenance teams can address potential issues before they become serious problems, ensuring public safety and reducing repair costs.

The Future of Thermal Imaging

As technology advances, thermal cameras are becoming more accessible and sophisticated. Integration with AI and machine learning is on the rise, allowing for automated detection and analysis of thermal images. This could revolutionize fields like security, where AI can identify unusual patterns and alert authorities in real-time.

AI and Machine Learning Integration

The integration of AI allows for real-time analysis and decision-making. For example, in security systems, AI can automatically detect unusual heat patterns indicative of a potential threat, streamlining the response process and enhancing safety.

Common Mistakes and How to Avoid Them

When using thermal cameras, several common mistakes can impede effective use:

- Ignoring Emissivity: Many users overlook the impact of emissivity on readings. Always adjust for material properties.

- Overreliance on Technology: While powerful, thermal cameras should be used alongside other tools and expert analysis.

- Neglecting Environmental Factors: Forgetting to account for weather conditions can lead to inaccurate interpretations.

Avoiding these pitfalls involves a combination of proper training, regular equipment checks, and comprehensive understanding of the technology.

Training and Education

Proper training can prevent many common mistakes. Users should be educated on how to adjust settings based on environmental factors and material properties, ensuring accurate and reliable results.

Thermal cameras remain indispensable tools in various industries due to their ability to capture thermal data that is not visible to the naked eye. They provide valuable insights, enhance safety, and improve efficiency across a wide range of applications. As technology continues to evolve, the potential for thermal imaging will only expand, offering even greater benefits and opportunities.

Continuous Development

The ongoing development in sensor technology and data processing capabilities will likely lead to even more compact and affordable thermal cameras. This evolution will open up new applications, from personal security devices to advanced medical diagnostics, making thermal imaging a standard tool in more fields.