The realm of healthcare has been dramatically transformed by the innovative technology of 3D printing, offering a plethora of practical applications that are revolutionizing the industry. This technology’s versatility and precision have opened new possibilities, enhancing patient care and streamlining medical processes in ways previously unimaginable. Let’s delve deeper into how 3D printing is making waves in healthcare, with more detailed insights and examples. The transformative power of 3D printing lies in its ability to convert digital designs into physical objects, layer by layer. This process not only allows for unprecedented customization but also significantly reduces the time and cost associated with traditional manufacturing methods. In healthcare, these advantages translate into tailored medical solutions, faster production of critical devices, and the democratization of healthcare resources, especially in underserved areas.

Customized Implants and Prosthetics

One of the most prominent uses of 3D printing in healthcare is the creation of customized implants and prosthetics tailored to each patient’s unique anatomy. Traditional methods often involve a one-size-fits-all approach, which can lead to discomfort and improper fit. However, 3D printing allows for precise design and production, resulting in better-fitting and more effective solutions for individuals in need of these devices.

Case Study: A Perfect Fit

Consider the case of Emma Lavelle, a young girl born with arthrogryposis, a condition that limits joint movement. Traditional prosthetics were cumbersome and ineffective for her needs. Using 3D printing, a team was able to design a custom exoskeleton that allowed Emma to move her arms freely—a life-changing development that dramatically improved her quality of life.

The customization aspect of 3D printing ensures that implants and prosthetics align perfectly with the patient’s individual needs, leading to improved comfort, functionality, and overall patient satisfaction. This approach not only enhances the physical compatibility of these devices but also addresses the psychological aspect of patient care by providing solutions that feel personal and tailored.

Beyond Limbs: Dental Applications

In addition to limb prosthetics, 3D printing is making significant strides in dental applications. Dentists can now use 3D printing to create perfectly fitted crowns, bridges, and even dentures. By scanning a patient’s mouth and using CAD software, dental professionals can design and print devices that fit with precision, reducing the likelihood of discomfort and the need for adjustments.

Real-world Tip: Iterative Design and Quick Adjustments

One of the practical benefits of using 3D printing for implants and prosthetics is the ability to iterate designs quickly. If a prototype doesn’t fit perfectly, adjustments can be made in the CAD model, and a new version can be printed within hours. This rapid prototyping capability is invaluable, particularly for pediatric patients who may require frequent updates to their prosthetics as they grow.

Medical Models and Surgical Planning

3D printing enables the creation of intricate medical models that help surgeons visualize complex procedures before entering the operating room. These models are particularly beneficial for surgeries involving delicate areas like the brain or heart, where precision is critical.

Enhancing Surgical Precision

Surgeons can use these detailed models to simulate surgeries, identify potential challenges, and develop strategies to optimize the surgical process. For example, a team of cardiac surgeons used a 3D-printed heart model to plan a tricky operation on a newborn with a congenital heart defect. By practicing on the model, the surgeons were able to refine their technique, ultimately reducing the time spent in surgery and improving the child’s recovery time.

Common Practices

- Pre-Operative Planning: Surgeons often use 3D models to explore different surgical approaches, reducing the risk of complications.

- Patient Education: These models also serve as educational tools, helping patients and their families understand the procedure and set realistic expectations.

Case Study: Neurosurgery

In neurosurgery, where millimeters can make the difference between success and disaster, 3D-printed models of a patient’s brain can aid in mapping out surgical routes. A study from the Mayo Clinic found that using these models significantly decreased operating times and improved surgical outcomes, underscoring the practical impact of 3D printing in high-stakes medical scenarios.

Practical Insight: Cost and Accessibility

While the initial cost of setting up a 3D printing lab can be substantial, the long-term savings in terms of reduced surgical times and improved outcomes often justify the investment. Moreover, as technology advances, the cost of 3D printers and materials continues to decrease, making this technology more accessible to a wider range of medical facilities, including those in resource-limited settings.

Drug Development and Personalized Medicine

With 3D printing, pharmaceutical companies can expedite the drug development process by creating custom dosage forms and drug delivery systems. This technology also facilitates the production of personalized medicine, allowing for tailored treatment plans based on individual patient needs and genetic profiles.

Personalized Dosage Forms

Imagine a diabetic patient who requires a personalized mix of medications. Traditional pill production would require multiple prescriptions, but 3D printing can combine these into a single, custom-printed pill. This not only simplifies the patient’s regimen but also enhances adherence and effectiveness.

Reducing Adverse Reactions

By individualizing drug dosages and delivery mechanisms, 3D printing plays a crucial role in optimizing treatment outcomes and reducing the risk of adverse reactions. For example, in cancer treatment, where precise dosing is critical, 3D printing can produce patient-specific medication batches that minimize toxicity while maximizing therapeutic effects.

Case Study: FDA-Approved 3D-Printed Drug

In 2015, the FDA approved the first 3D-printed drug, Spritam, designed to treat epilepsy. The drug’s porous structure allows it to dissolve rapidly, making it easier to swallow for patients who struggle with traditional tablets. This approval marked a significant milestone, paving the way for more personalized and innovative drug formulations.

Practical Consideration: Regulatory Hurdles

While the potential benefits of 3D-printed drugs are vast, navigating the regulatory landscape remains a challenge. Pharmaceutical companies must work closely with regulatory bodies to ensure that new formulations meet rigorous safety and efficacy standards. This collaboration is crucial to fostering innovation while maintaining patient safety.

Biofabrication and Tissue Engineering

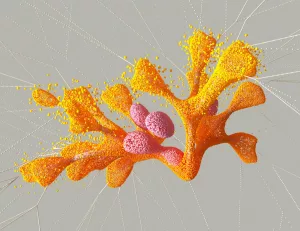

Advancements in biofabrication and tissue engineering have been accelerated by 3D printing, enabling the creation of complex tissues and organs for transplantation. This groundbreaking approach holds immense promise for addressing the shortage of donor organs and improving outcomes for patients in need of transplants.

Building Organs Layer by Layer

The precise layer-by-layer construction enabled by 3D printing technology allows researchers to develop bioengineered tissues and organs with enhanced functionality and compatibility. A notable example is the development of a 3D-printed ear, created from a combination of biodegradable materials and living cells, which has shown great potential in reconstructive surgery.

Addressing Organ Shortages

The ability to print organs on demand could revolutionize transplantation. While still in the experimental phase, the potential to print kidneys, livers, or hearts would alleviate the burden on donor lists, offering new hope for patients awaiting life-saving transplants.

Case Study: Bioprinted Skin

Researchers at Wake Forest Institute for Regenerative Medicine have successfully bioprinted skin tissue for burn victims. This skin can be printed directly onto the wound using a patient’s own cells, reducing the risk of rejection and accelerating the healing process. This innovation underscores the potential of 3D printing to transform reconstructive medicine.

Practical Insight: Ethical Considerations

The potential to create human tissues and organs raises ethical questions that must be addressed as technology advances. Issues such as consent, equity in access, and the moral implications of creating human tissues in a lab require careful consideration and open dialogue among scientists, ethicists, and policymakers.

Remote Healthcare and Telemedicine

3D printing has the potential to revolutionize remote healthcare and telemedicine by enabling the on-demand production of medical supplies, such as prosthetics and equipment. This technology could greatly benefit underserved populations and patients in remote locations by providing access to essential healthcare resources.

Bridging the Gap

By decentralizing the production of medical devices and supplies, 3D printing empowers healthcare providers to deliver timely and customized solutions to patients in remote areas. For instance, a rural clinic in Africa was able to produce prosthetic limbs on site, significantly reducing costs and delivery times compared to traditional manufacturing and shipping.

Enhancing Telehealth Services

3D printing supports telemedicine by allowing healthcare providers to send digital files of medical devices to remote locations, where they can be printed locally. This not only saves time but also ensures that patients receive the most up-to-date and relevant medical devices.

Practical Implementation: Mobile 3D Printing Units

Some organizations are experimenting with mobile 3D printing units that can travel to remote areas, equipped with printers capable of producing everything from splints to customized medical tools. These mobile units can be especially critical in disaster zones or areas with limited infrastructure, providing immediate relief and reducing dependency on external supply chains.

Educational and Research Applications

3D printing’s impact isn’t limited to direct patient care; it also plays a critical role in medical education and research.

Training the Next Generation

Medical students can benefit from 3D-printed anatomical models, which provide a hands-on learning experience that is far superior to traditional textbook illustrations. These models allow students to explore human anatomy in intricate detail, enhancing their understanding and preparing them for real-world medical challenges.

Accelerating Research

In research, 3D printing facilitates the rapid prototyping of medical devices and instruments. Researchers can quickly iterate on designs, leading to faster innovation cycles and more effective solutions for complex medical problems.

Case Study: Veterinary Medicine

3D printing is also making waves in veterinary medicine. Veterinary schools use 3D-printed models to train students in procedures on animals without the ethical concerns associated with live animal testing. This approach not only enhances learning but also improves animal welfare.

Practical Tip: Collaborative Innovation

Collaboration between universities, hospitals, and tech companies can accelerate the development of 3D printing applications in healthcare. By sharing resources and expertise, these partnerships can drive innovation and bring cutting-edge solutions to market more quickly and efficiently.

Regulatory and Ethical Considerations

As with any emerging technology, the integration of 3D printing into healthcare comes with regulatory and ethical challenges.

Navigating Regulations

Ensuring the safety and efficacy of 3D-printed medical devices requires robust regulatory frameworks. Organizations like the FDA are actively developing guidelines to address these challenges, balancing innovation with patient safety.

Ethical Implications

The ability to print human tissues and organs raises complex ethical questions. Issues surrounding access, consent, and the potential for misuse must be carefully considered as the technology advances.

Practical Insight: Global Standards

As 3D printing in healthcare is a global phenomenon, international cooperation is essential to establish standardized regulations and ethical guidelines. This collaboration can help ensure that patients worldwide benefit from the technology while minimizing risks and ethical concerns.

Future Prospects and Innovations

Looking ahead, the future of 3D printing in healthcare is bright, with ongoing research and development paving the way for even more revolutionary applications.

Emerging Technologies

- Bioprinting: Advances in bioprinting are bringing us closer to the creation of functional, transplantable organs.

- Nanotechnology: Combining 3D printing with nanotechnology could lead to breakthroughs in drug delivery systems and cancer treatments.

Long-Term Vision

The integration of artificial intelligence with 3D printing could further enhance the customization and efficiency of medical solutions, offering unprecedented levels of personalization and precision in patient care.

Practical Consideration: Skills and Training

As 3D printing becomes more integrated into healthcare, there will be a growing need for professionals trained in both medical and technical aspects of the technology. Investing in education and training programs will be crucial to ensure that the healthcare workforce is equipped to harness the full potential of 3D printing.

3D printing is not just a trend; it’s a transformative force that is reshaping the landscape of healthcare. From improving surgical outcomes to making healthcare more accessible, its impact is profound and far-reaching. As we continue to explore and expand its applications, the potential benefits for patients and healthcare systems worldwide are limitless.